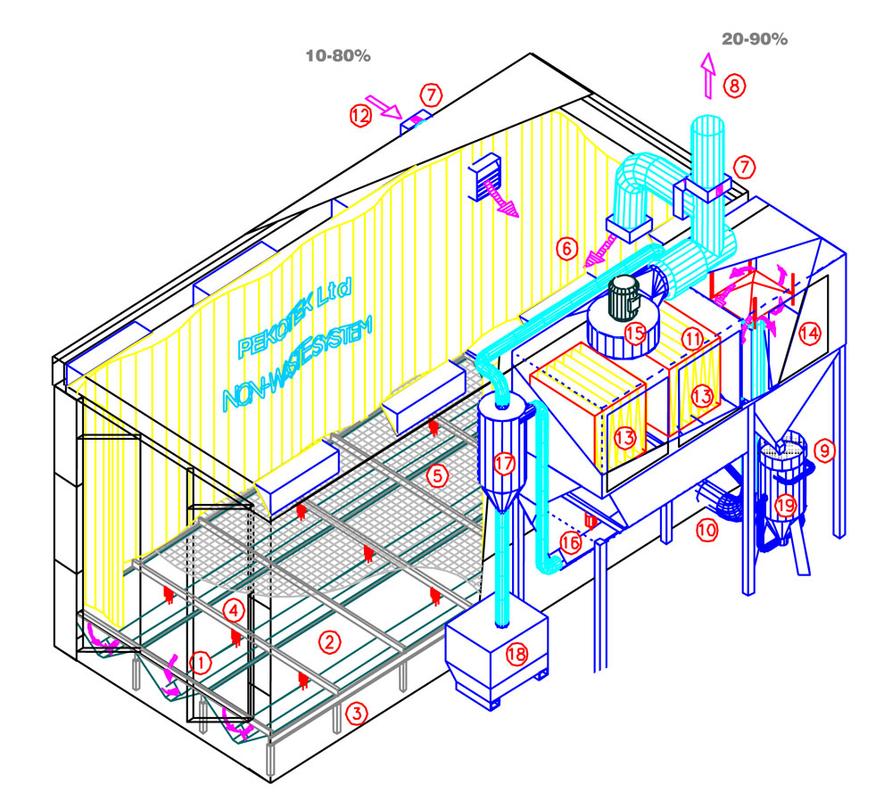

Air operated Non-Waste system

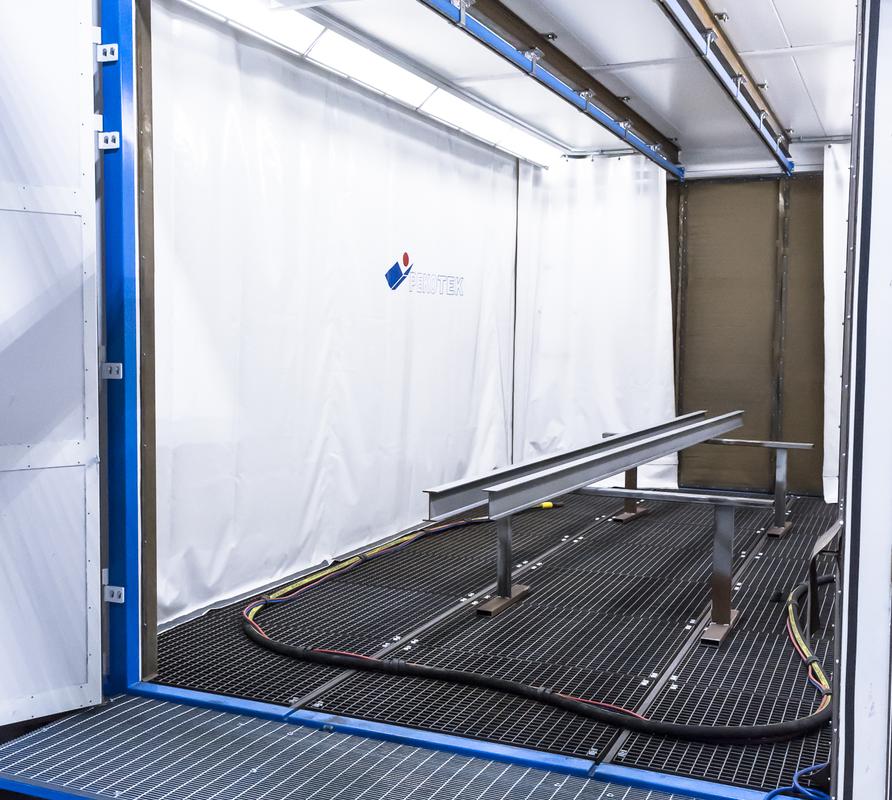

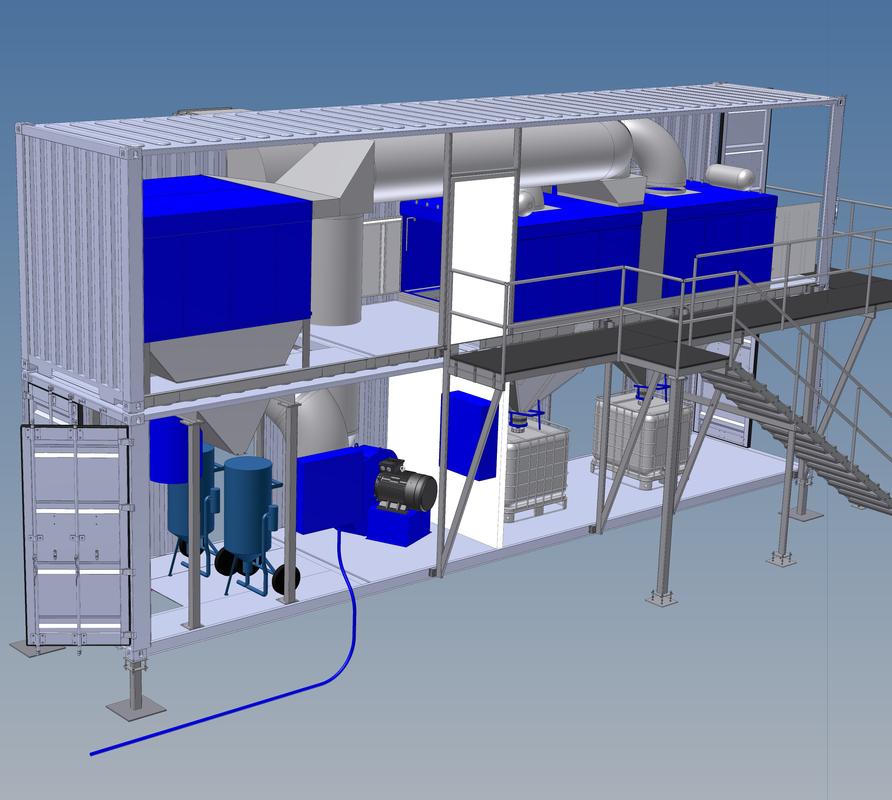

Pekotek's own patented Non-Waste grit recycling and cleaning system is simple and therefore energy-efficient and reliable. The air-recirculation system keeps the grit clean and dry. Transfer and grit recycling, the ventilation of the blowing chamber, the dust removal and the waste transfer are carried out with one fan. The fan is in clean air after the filter.